Why simulate manufacturing processes?

With FlexSim you can solve problems in a practical way: whether understanding how your current process is, finding waste, making better use of your resources or testing new improvement proposals.

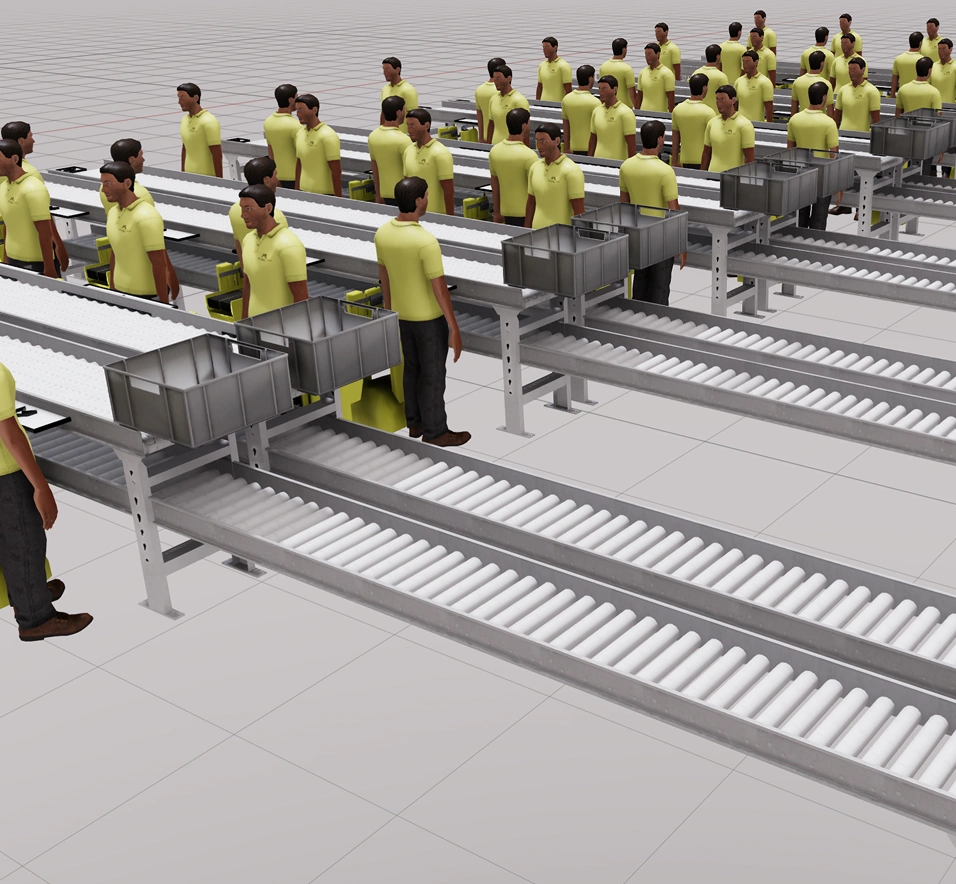

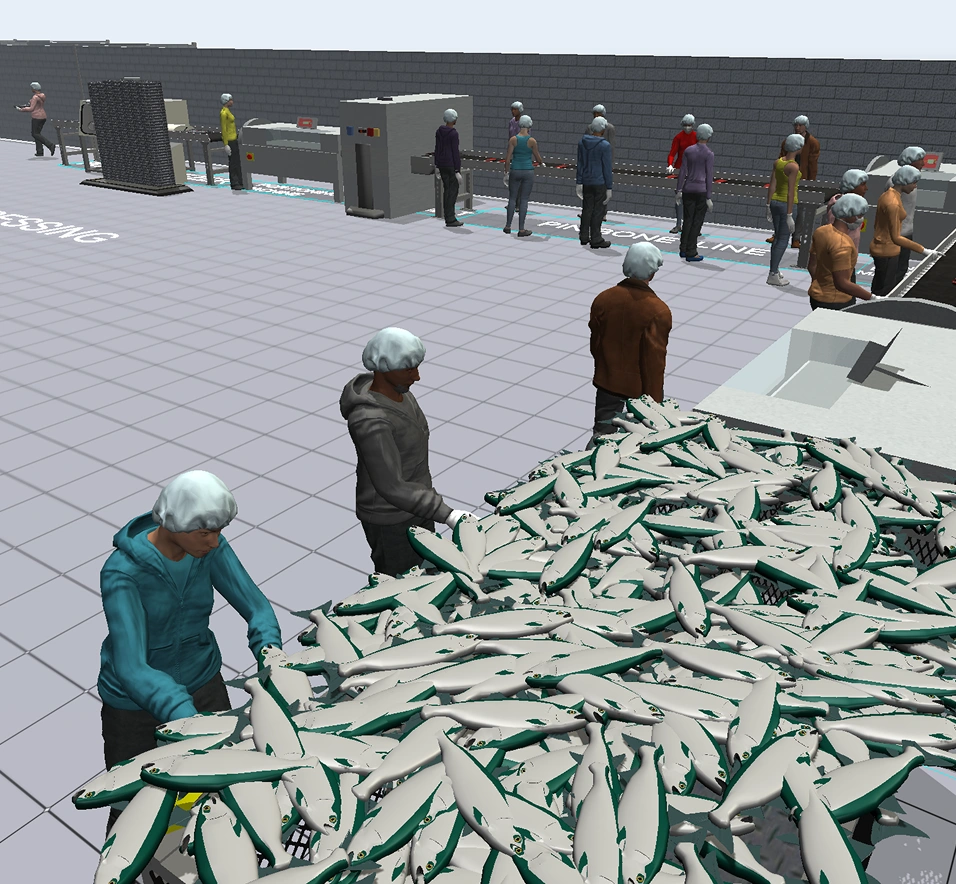

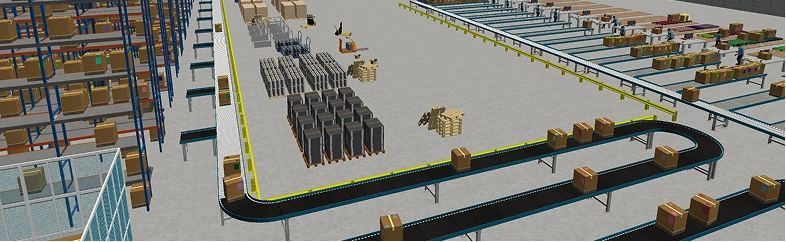

You can simulate any type of process: from a small operation such as a production line or a work cell, to an entire complete plant.

In addition, it is possible to include important variables such as cycle times, number of resources, inventories, unscheduled stops, defective material, maintenance, costs and much more.

Avoid Risks and reach your goals

Simulating manufacturing processes is an accessible, agile, risk-free route to understand, experiment and learn from our processes. Simulate from individual processes to entire plants easily and test different scenarios without risk.